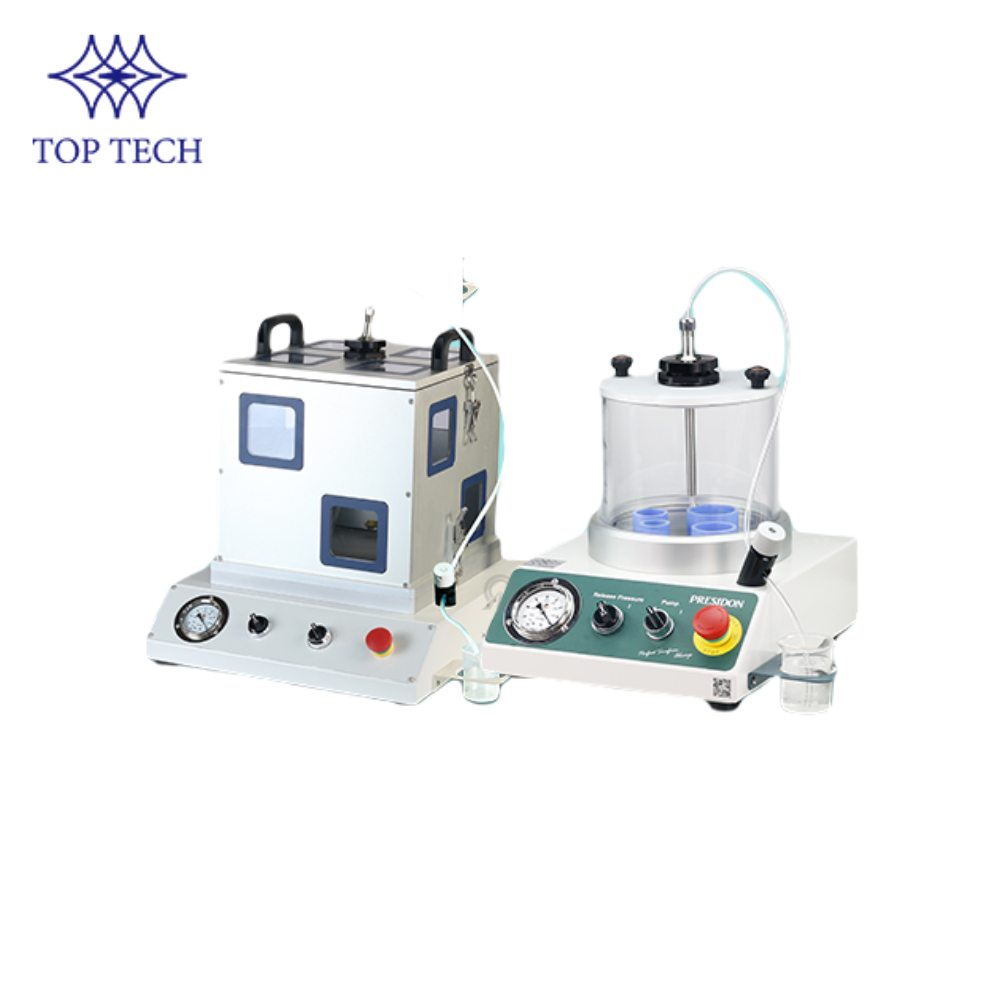

TOP TECH|Vacuum Impregnation

Feature :

- Intuitive Operation Interface: Analogy pressure gauge precisely indicates the value of vacuum. The switches for operation are easy to understand. Emergency stop confirms the safety of machine operation.

- Adjustable epoxy dispenser design : With the epoxy dispenser, the user can fill mounting cups at any speed and any position. Maximize the utility of the vacuum chamber.

- Maximally decrease the bubbles around the samples : During the evacuation, the pressure will decrease, the bubbles will expand and go up. When the vacuum is released, the bubbles will burst under the different pressure from inside to outside. Maximally decrease the bubbles around the sample.

- Embedding of the porous samples : Maximally decrease the bubbles in the porous sample. Improve the filling of the pores inside the sample and optimize the edge retention.

- Optimize the edge retention : Let the epoxy fill the samples under the vacuum situation, the bubbles around the sample can be maximally decreased. The epoxy can flow through the sample easily, without being blocked by air. Optimize the edge retention of the fragile samples.

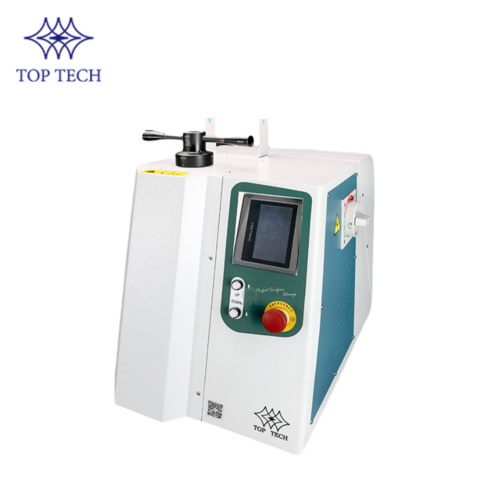

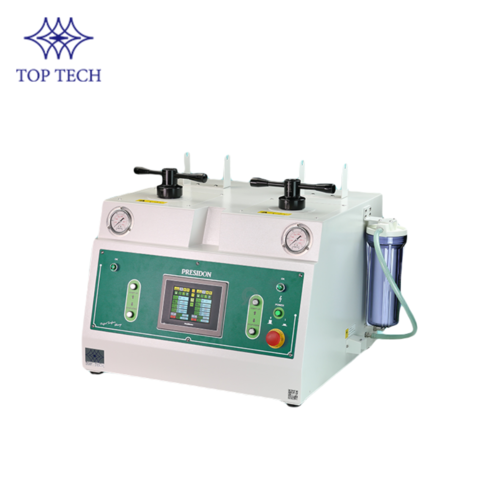

- Spacious vacuum chamber and multiple viewing windows (MV01) : A separable metal vacuum chamber design, with multiple viewing windows, not only considers the stability and operational efficiency but also confirms the convenience of cleaning and operation.

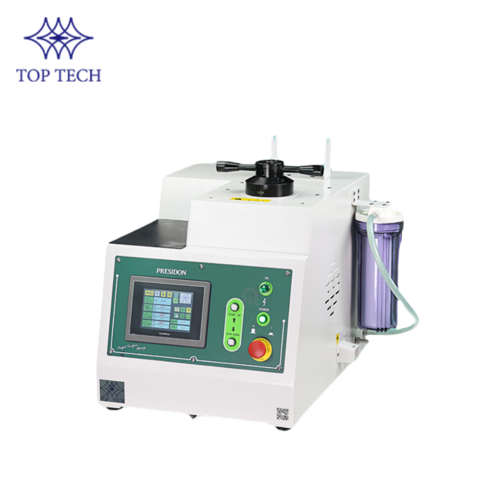

- Transparent vacuum chamber design (MV02 ) : Precision mounting resin filling with full perspective observation saves consumables and improves operational efficiency.

|

Model |

MV01 |

MV02 |

|

Max. Vacuum Pressure |

-600 mm-Hg(-0.799 bar/-79.993 kpa/ -11.602 psi) |

-500 mm-Hg (-0.666 bar/-66.661 kpa/ -9.668 psi) |

|

Can be customized between -350~-600 mm-Hg |

||

|

Pump Motor Power (W) |

300 |

180 |

|

Pump Dimension (W x D x H) |

170 x 320 x 210 mm |

155 x 235 x 210 mm |

|

Pump Weight (kg) |

9 |

7 |

|

Pump Flow (L/min) |

86 |

50 |

|

Vacuum Chamber Size |

300 x 330 x 300 mm |

Ø180 x 160 mm |

|

Pressure Relief Method |

Switch Control |

|

|

Machine Dimension (W x D x H) |

540 x 550 x 560 mm |

390 x 400 x 410 mm |

|

Machine Weight (kg) |

45 |

20 |

|

Power Supply |

AC 110/220V 1Ø |

|

|

Accessories |

MV010212 Silicone foam strip 2pcs, High Flow Epoxy set (Epoxy resin 950ml, hardener 20ml and mixer bag) 1set, Vacuum pump 1set |

HM090190 O-ring 2pcs, Acrylic observed cover 1pc, High Flow Epoxy set (Epoxy resin 950ml, hardener 20ml and mixer bag) 1set, Vacuum pump 1set |