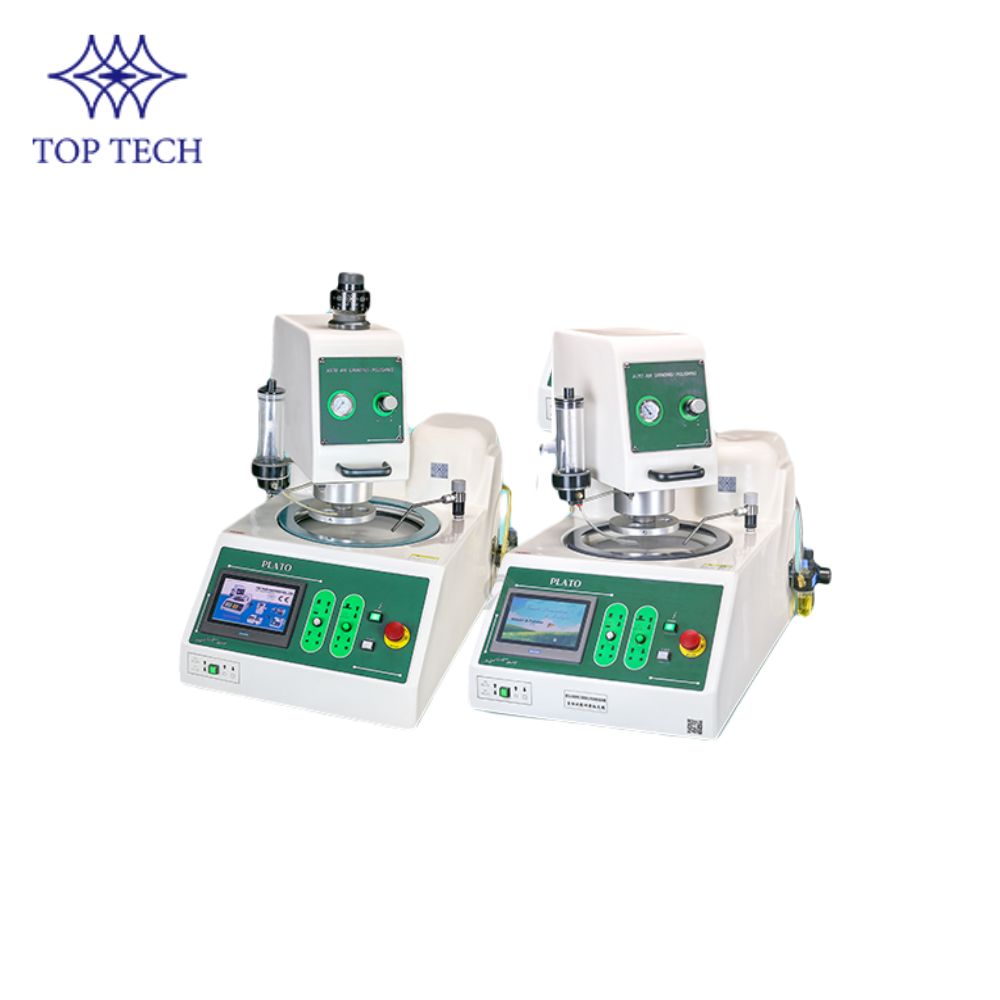

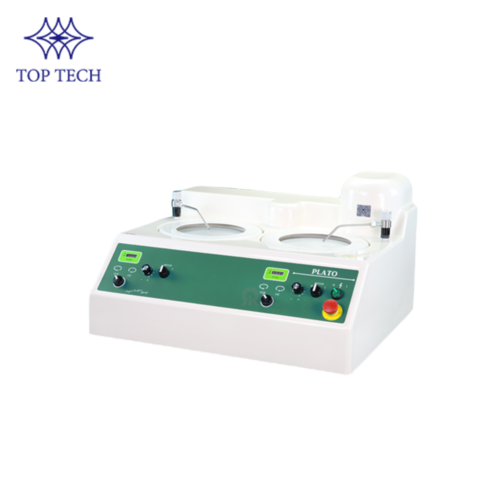

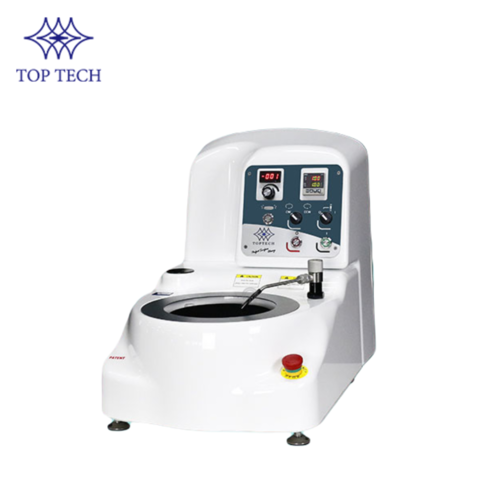

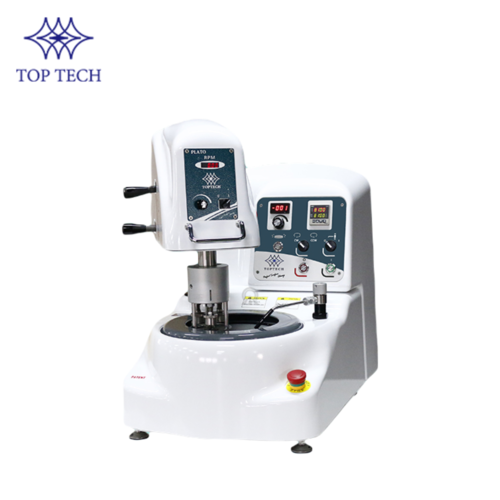

TOP TECH|Air Pressure Type Automatic Grinder & Polisher

Feature :

- Air pressure force : Supplying of stable down force ensures the better flatness of grinding/polishing.

- Quick-released sample holder : Quick-released design of sample holder is easy to clean, and is able to avoid the cross-contamination during the preparation process.

- Fiber-Reinforced Plastic (FRP) body cover : FRP body cover design is easier for maintenance and endurable.

- Multi-functional control panel : HD & colorful touch panel with intuitive HMI design is able to accesses the different parameters quickly, and is also equipped 100 set of parameter memory function.

- High effective brushless motor : Low rotational speed and high torque ensures the precision of grinding/ polishing, and also has a longer lifespan.

- Multiple choices of platens are suitable for various consumables : Platen can be rapidly replaced. According to the feature of the consumables, such as PSA back SiC papers, plain back SiC papers, diamond discs, and polishing cloths, to apply with suitable platens.

- Compatible with dispenser (Option) : Opting for a dispenser can distribute diamond suspension or aluminum suspension automatically.

- Sample Pistons : Sample pistons will lower down lightly to prevent the surface of the specimen from damage.

- Individual Force & Central Force : The Individual force is flexible for sample preparation, while the central force is suitable for irregular shape sample grinding. The sample holder can be customized according to the shape or the size of the sample, which will ensure the better flatness .

- Platen speed and rotational direction adjustable : According to the sample of material to adjust the rotational speed and direction, which ensures with better effect of grinding/polishing.

- Dosing system (Option) : Equipped dosing system can distribute aluminum suspension or diamond suspension, which greatly reduces the usage of the labor force.

- Micrometer adjustment design (FS-R-M) : The micrometer adjustment devise is an optional function, which can set the grinding depth to avoid over grinding and affect the observation.

|

Model |

FS-R |

FS-R (Micrometer) |

||

|

Platen Size |

Ø254 mm |

Ø304.8 mm |

Ø254 mm |

Ø304.8 mm |

|

Platen Quantity |

1 |

|||

|

Sample Quantity |

3 or 5 |

|||

|

Noise Level (dB) |

63~67 |

|||

|

Sample Size |

Ø25 / Ø32 / Ø40 (Special sample size can be customized) |

|||

|

Individual Force (kg) |

1~8 |

|||

|

Central Force (kg) |

6~25 |

|||

|

Platen Motor Power (W) |

750 |

|||

|

Platen Rotational Speed (rpm) |

50~600 (Special rotational speed can be customized) |

|||

|

Head Motor Power (W) |

90 |

|||

|

Head Rotational Speed (rpm) |

80 (Special rotational speed can be customized) |

|||

|

Timer (s) |

Max. 60000 (1000min) |

|||

|

Memory Mode (set) |

100 (Set Time and rotational speed) |

|||

|

Machine Dimension(W x D x H) |

500 x 800 x 750 mm |

500 x 800 x 860 mm |

||

|

Machine Weight (kg) |

110 |

120 |

112 |

122 |

|

Water Inlet Pipe Size (mm) |

10mm pipes (Inlet Ø10-Outlet Ø15) |

|||

|

Water Outlet Pipe Size (mm) |

32mm pipes (Inlet Ø32-Outlet Ø36) |

|||

|

Power Supply (V) |

AC 220 1Ø |

|||

|

Accessories |

Grinding Platen 1pc, O-ring 1pc, Anti-Splash Cover 1pcs, Silicon Carbide Paper 8pcs, Polishing Cloth 2pcs, Aluminum Oxide Powder 100g, PU Pipe 6m, P20F0026A Dosing system, Leveler 1pc |

|||

|

Option |

P20F0027 Dispenser Set- single bottle, P20F0028 Dispenser Set- four bottles, P20Z06-R1 Manual Leveler Platform |

|||