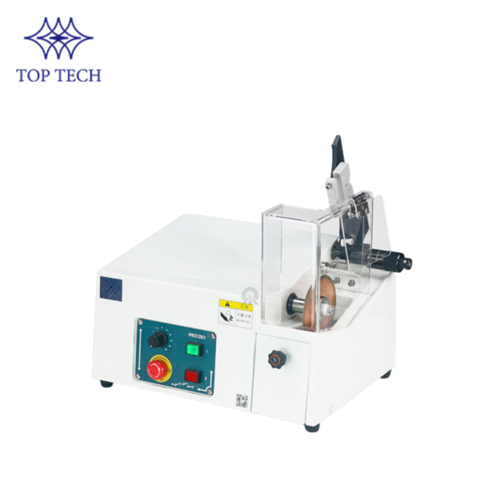

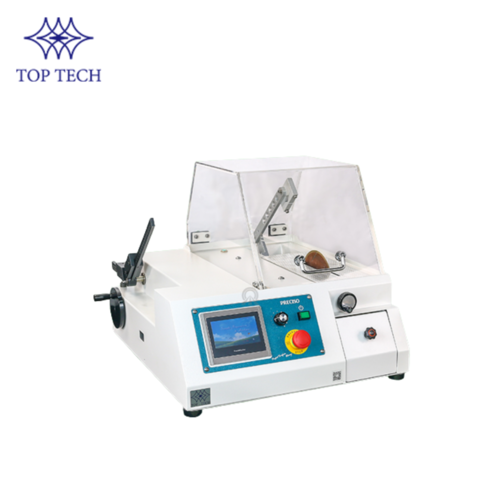

TOP TECH|Precision Cutting Machine

Feature :

- Safety sensor for the top cover: The safety sensor for the top cover confirms the spindle will stop automatically when the top cover is opened during operation.

- Front limit sensor and back limit sensor : The front limit sensor and the back limit sensor control the travel distance for feeding

- Magnetic interlock system (Optional) : After the spindle is started, the top cover can’t be opened during the operation.Wait for 10 seconds after the spindle is stopped, the top cover can be opened.

- Intuitive panel for convenient operation : Intuitive panel with high recognition graphics is easy to understand. It decreases operating time significantly.

- LED light : LED light enhances the observation of the cutting process and illuminates the cutting space.

- Magnetic water spray hose : Magnetic water spray hose easily cleans the cutting chamber and vise.

- Feeding clutch (CK200B )/ Hand wheel : Feeding clutch switches manual mode and auto mode quickly. Feeding rate is controlled by the hand wheel, the operation is easy.

- Storable design for the coolant tank : A storable design for the coolant tank increases the space utilization.

- Variable spindle rotation speed (Optional) : Frequency transformer for variable spindle rotation speed (plus or minus 50%)

- Horizontal movement vise (Standard) : Left and right vise can each be moved 25mm in horizontal direction (Y-axis) / Right vise can be moved 75mm in X-axis (feeding) / The maximum opening of the vise is 60mm(Please refer to the appendix 1 for the maximum cutting capacity)

- Separated horizontal movement platform (Optional) : Left and right platform can each be moved 25mm in horizontal direction (Y-axis) / The maximum opening of the vise is 70mm(Please refer to the appendix 2 for the maximum cutting capacity)

|

Model |

CK200B (Auto) |

CK200M(Manual) |

|||||

|

Travel Distance (mm) |

200 |

||||||

|

Motor Power (HP) |

1 |

2 |

3 |

1 |

2 |

3 |

|

|

Total Watt (W) |

900 |

1650 |

2400 |

850 |

1600 |

2350 |

|

|

Idling Noise Level (dB) |

70~72 |

70~74 |

70~75 |

70~72 |

70~74 |

70~75 |

|

|

Cutting Ability (mm) |

Ø35 |

Ø50 |

Ø60 |

Ø35 |

Ø50 |

Ø60 |

|

|

Cut-off Blade (mm) |

Ø230 x 31.75 |

Ø255 x Ø31.75 |

Ø230 x 31.75 |

Ø255 x Ø31.75 |

|||

|

Flange Diameter (mm) |

Ø60 |

Ø85 |

Ø60 |

Ø85 |

|||

|

Feeding method |

Auto / Manual |

Home point return after cutting / Button & Hand wheel control |

Manual: Hand wheel control |

||||

|

Feeding Rate (mm/min) |

Standard:10~150, Option:5~75 (Low feeding rate can be customized) |

3000(60Hz) or 2500(50Hz) |

|||||

|

Rotational Speed (rpm) |

3000(60Hz) or 2500(50Hz) |

3000(60Hz) or 2500(50Hz) |

|||||

|

Cutting Vise (Standard) |

Horizontal movement vise |

||||||

|

Vise Dimension (mm) |

Max. 60*45 |

||||||

|

Vise Movement in Y-axis (mm) |

Separated movement: 25mm |

||||||

|

Coolant Pump |

1/8HP 3Ø |

||||||

|

Coolant Tank Capacity (L) |

50 |

||||||

|

Coolant Tank Dimension (W x D x H) |

370 x 550 x 600 mm |

||||||

|

Coolant Tank Weight (kg) |

40 |

||||||

|

Machine Dimension (mm) |

830 x 930 x 1320 mm |

||||||

|

Machine Weight (kg) |

226 |

230 |

250 |

212 |

218 |

230 |

|

|

Standard Accessories |

Wrench 2 sets, Cut-off wheel 2 pcs, Cutting coolant 3L |

||||||